'Sagitta' The work begins.

Having now removed all the fittings that could be taken off the hull without causing damage I am now in a better position to decide what sort of restoration Sagitta will be undergoing. As I have already stated the hull is actually in very good condition, as is the deck. The deck has lifted in three places, not a difficult fix and there is a scratch on one side of the hull. As the varnish on both the hull and the deck is in good condition and there are just a few signs of wear from deck fittings and small dints here and there I have decided to cut the varnish back with wet and dry using water as well and leave all the distress marks, after all the yacht is over 60 years old and any aggressive sanding and scraping will only remove the patina built up in the mahogany planking to the hull and the thin surface veneer to the decking. That means that what you see at the lake will essentially be a 1950’s yacht in very good condition with not too many shiny bits to look out of place.

The Mast and booms have been covered with varnish and in several places corrosion from the alloy has broken through and the varnish has peeled and discoloured over the entire surface, not a pretty site but I have a plan to restore these items, but need to experiment a little as many of the fixed fitting are whipped to the mast and booms and I don’t want to disturb these fixtures. The wire that is stretched up the entire length of the mast to which the main sail hooks on to must have taken the builder hours of fiddly work and a gallon of patience so it’s not in my place to rip it all off just so that I can polish the alloy!

The vane steering gear was missing as is the case with many yachts of this style that have come to light over the years and as I’m not up to rushing around the lake after a six foot plus yacht with a mind of it’s own it will be converted to radio control with a rudder servo and sail winch. To this end there will be no butchery of the hull, deck or hatch cover but this is an area that I will have to take advice from others. One area that may well need to be addressed is that of steering, these yachts were it seems designed to go in straight lines and might not take too kindly to sharp turns, we shall see, there is always the option of a bolt on extension to the rudder.

What ever form the restoration takes, major, minor, and whatever needs replacing, it is my intension that with the re- fitting of vane steering gear and the removal of the rc equipment Sagitta will be as the builder intended in mechanics and looks and able to sail as he intended, to this end any parts that are not required after the rc conversion (and there will be quite a few small items) will be fixed within the hull for someone else to reinstate if they so desire, in years to come, I think the term is ‘future proofing’.

The Mast and booms have been covered with varnish and in several places corrosion from the alloy has broken through and the varnish has peeled and discoloured over the entire surface, not a pretty site but I have a plan to restore these items, but need to experiment a little as many of the fixed fitting are whipped to the mast and booms and I don’t want to disturb these fixtures. The wire that is stretched up the entire length of the mast to which the main sail hooks on to must have taken the builder hours of fiddly work and a gallon of patience so it’s not in my place to rip it all off just so that I can polish the alloy!

The vane steering gear was missing as is the case with many yachts of this style that have come to light over the years and as I’m not up to rushing around the lake after a six foot plus yacht with a mind of it’s own it will be converted to radio control with a rudder servo and sail winch. To this end there will be no butchery of the hull, deck or hatch cover but this is an area that I will have to take advice from others. One area that may well need to be addressed is that of steering, these yachts were it seems designed to go in straight lines and might not take too kindly to sharp turns, we shall see, there is always the option of a bolt on extension to the rudder.

What ever form the restoration takes, major, minor, and whatever needs replacing, it is my intension that with the re- fitting of vane steering gear and the removal of the rc equipment Sagitta will be as the builder intended in mechanics and looks and able to sail as he intended, to this end any parts that are not required after the rc conversion (and there will be quite a few small items) will be fixed within the hull for someone else to reinstate if they so desire, in years to come, I think the term is ‘future proofing’.

These two pictures show the hull after being sanded down and a coat of satin varnish applied, in the picture on the left you can see the scratch, made more pronounced by the edges taking the varnish into the exposed grain and becoming raised. It'll be fine when it's had a few more coats.

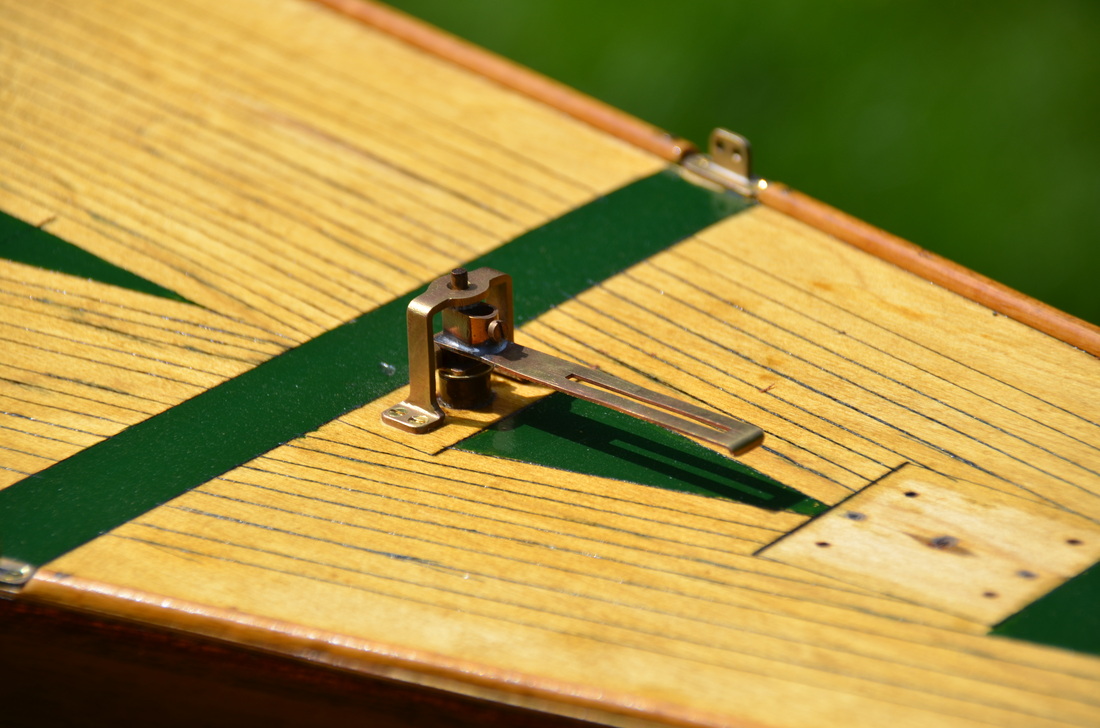

The light aerofoil shape at the root of the keel is in fact a beautifully crafted 1/8" brass plate fixed to the hull, this mates with a matching one on the keel, the keel really does have to come off before storing the hull, because of the weight and the brass plates ensure that there is no wear takes place which would happen if the joint was just wood to wood.

The light aerofoil shape at the root of the keel is in fact a beautifully crafted 1/8" brass plate fixed to the hull, this mates with a matching one on the keel, the keel really does have to come off before storing the hull, because of the weight and the brass plates ensure that there is no wear takes place which would happen if the joint was just wood to wood.

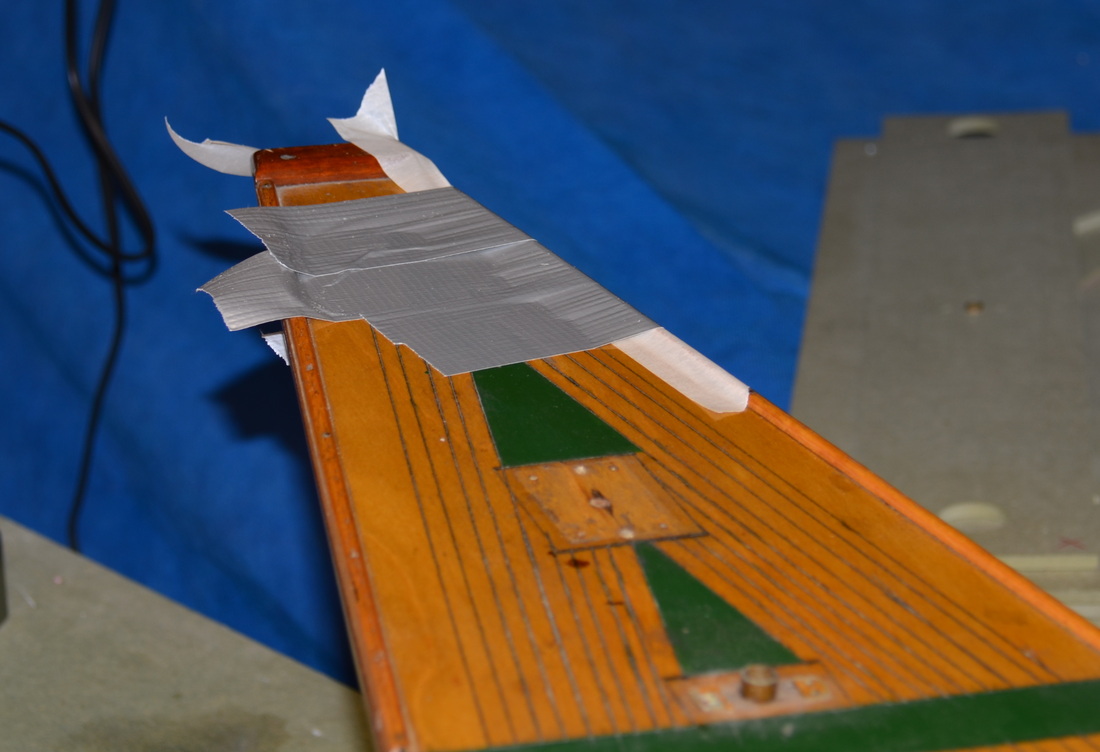

A quick look at one of the three places where the deck has lifted, I forced 24hr Araldite into the crack and left to cure. Pondering how to clamp the deck to the hull with all the compound curves I ended up holding it down with gaffer tape, with no damage to the varnish and no sign of movement, I thought that rubber bands would not hold the parts together and some kind of strap wound tightly would damage the timber.

As you can see the hardware is in a bit of a mess and I don't want to end up with a polished alloy finnish so what to do? Well I have just completed one of the small booms with a great deal of success and retained the whipping intact by covering in Nitromors paint stripper, putting it in a polythene bag and leaving overnight.

Next day wash of the paint stripper and all the varnish came off, a good deal of the corrosion came off as well and only left slight marking which I feel is quite acceptable given the age of the boat.

Next day wash of the paint stripper and all the varnish came off, a good deal of the corrosion came off as well and only left slight marking which I feel is quite acceptable given the age of the boat.

As the hull nears completion the sheer size and weight of it will necessitate a strong and durable stand. The one that I received with it while being the original and in soft wood was not very pretty or for that matter durable so I decided to replace it. I do have a large baulk of Brazilian mahogany at the factory around 9"x4"x16' or there abouts, and I must say I was very tempted to chop a bit off to match the mahogany of the hull, but thought better of it so I settled for popping a few sticks of Marranti (roughly 2"x3/4" fin.,) sawn, through the four cutter ( I had to get one of the lads to machine it for me as I had forgotten how to set it up) and off to Bob Bakers' to use his workshop to cut to size and cut the angles. Again I could have done this at the factory but most of the machines are cnc controlled now and while they do a brilliant job it would have taken me a month of Sundays to figure how to operate them.

Bob a Master organ builder in a former life also gave me a piece of guardsman red felt about 1/4" thick for the hull to sit against and a nice piece of tan leather for the lead weight to rest on. both pieces of material were part of Bobs dwindling collection of spares for organs so I was very lucy, and I think the red baize makes all the difference to the look of the stand.

The two brass key like fittings sitting on the brass bar are in fact threaded and they retain the keel to the hull and also provide fixing for a carrying handle inside the hull. As I intend to put the RC equipment in the access hatch that the handle sits below this means that I will have to transfer the lifting points to outside the hull in the deck as I want to be able to lift the yacht in and out of the water without removing the electronics every time.

At this time I have ordered the sails, a working suit which was designed with the help of Dennys Warren as the fore sail that came with her may not have actually been for her and the main needed some refinement as well.

Bob a Master organ builder in a former life also gave me a piece of guardsman red felt about 1/4" thick for the hull to sit against and a nice piece of tan leather for the lead weight to rest on. both pieces of material were part of Bobs dwindling collection of spares for organs so I was very lucy, and I think the red baize makes all the difference to the look of the stand.

The two brass key like fittings sitting on the brass bar are in fact threaded and they retain the keel to the hull and also provide fixing for a carrying handle inside the hull. As I intend to put the RC equipment in the access hatch that the handle sits below this means that I will have to transfer the lifting points to outside the hull in the deck as I want to be able to lift the yacht in and out of the water without removing the electronics every time.

At this time I have ordered the sails, a working suit which was designed with the help of Dennys Warren as the fore sail that came with her may not have actually been for her and the main needed some refinement as well.

One of the major chores now completed with the re-varnishing of the hull and deck. To preserve the look of the yacht as it would almost certainly have been prior to being laid up the whole lot was washed in white spirit, sanded with 800 and 1000 grit wet and dry paper and given a couple of coats of gloss varnish.

I thought I had better post an update as there has been no progress with Sagitta over the last couple of weeks or so as I am still waiting for the new sails to arrive. Until I can start laying the runs of the lines and the entry and exit holes of same in the new superstructure for the RC then there is little point, in my view in ploughing on with the possibility of having to redo something.

4th November 2013.

While the sails arrived over a month ago I have not progressed much further while other projects have taken priority.

The sails seem fine though the main sail may have to be shortened a bit if it streches, so only time will tell. As varnished terylene sail material is still available, once the final sail shape and size has been determined I will be replacing the dacron ones as they are bright white and just don't look right. Being ten feet tall when rigged this is only possible outside and takes about twenty minutes so the first time sails will meet yacht will be at the International Model Boat Show at Warwick on the 8th to the 10th of November where it's undercover. I've installed two pully's to haul the sails up but at this stage the final method of rigging and securing of these lines will have to be worked out on the job so too speak.

28th November 2013

As the year draws to an end I have decided to mothball Sagitta until the warmer weather in the spring of 2014 as any further work on the rigging and sails that needs doing will have to be in the open air and a bit warmer, so untill then here is a picture of her at the Warwick Show 2013. And no, I have no plans to sell her.

While the sails arrived over a month ago I have not progressed much further while other projects have taken priority.

The sails seem fine though the main sail may have to be shortened a bit if it streches, so only time will tell. As varnished terylene sail material is still available, once the final sail shape and size has been determined I will be replacing the dacron ones as they are bright white and just don't look right. Being ten feet tall when rigged this is only possible outside and takes about twenty minutes so the first time sails will meet yacht will be at the International Model Boat Show at Warwick on the 8th to the 10th of November where it's undercover. I've installed two pully's to haul the sails up but at this stage the final method of rigging and securing of these lines will have to be worked out on the job so too speak.

28th November 2013

As the year draws to an end I have decided to mothball Sagitta until the warmer weather in the spring of 2014 as any further work on the rigging and sails that needs doing will have to be in the open air and a bit warmer, so untill then here is a picture of her at the Warwick Show 2013. And no, I have no plans to sell her.